Leading CNC Service Providers in Dandenong, Melbourne

We are experienced sheet metal fabricators servicing greater Melbourne. Our team has a long list of experience in the industry. Our expertise ranges from CNC folding and Laser cutting, to turret punching, metal perforations, MIG/TIG/Spot welding, powder coating and more.

Our network of suppliers and partners in the metal and engineering industries has given us the insight and hands-on experience needed to navigate CNC projects and equipment with precision during design, processing and production.

Make an Enquiry

We are an Australian family-owned business with an established market position who continually relies on leading technology to meet our commitment to providing quality materials and outcomes. Our CNC, CAD and CAM applications ensure that every piece we make hits the mark every time.

We never settle for less than high quality finishes and consistent, timely deliveries, with a range of custom design projects and specifications readily accommodated for by our manufacturing team.

If you’re looking for a local provider who knows the ins and outs of metalworking, speak with our in-house specialist team to see how you can leverage expedited services to streamline your manufacturing process today.

Melbourne’s Go-to for CNC Folding and Related Services

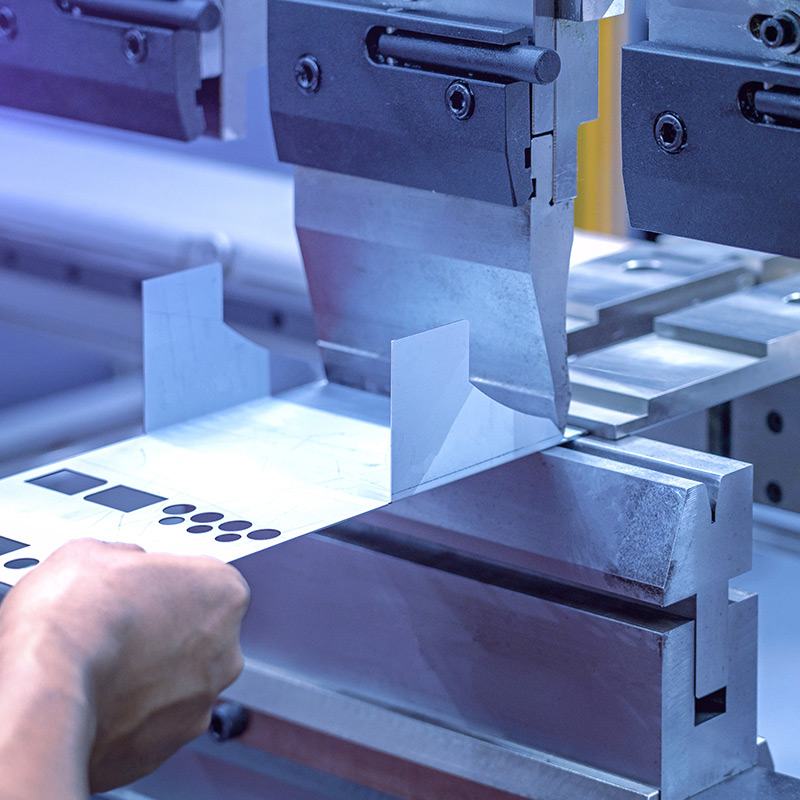

Our team is a leading manufacturer of metal products, and an industry go-to for CNC Folding services that can be customised to meet your needs. We produce superior metal projects with the use of multiple 7 axis CNC press brakes. We’re also equipped with laser safe guarding systems to help further achieve your most precise results. Some of the features of our CNC Folding services include:

- 250 tonne bending force

- 4200mm bending length

- Can accommodate all sized parts in mild steel, aluminium, and galvanized and stainless steel

- Fold up to 0.5mm to 8mm material thickness and up to 4200mm in length.

- Services: 7 axis CNC (Y1, Y2, X, R, Z1, Z2 & Crowning)

Knowing that many projects will require our team to customise cutting solutions to our client’s specifications and design, we work with you every step of the way to ensure that we measure as many times as necessary and cut once to give you the perfect product outcome.

Superior Products and Quality Outcomes

From hands-on design consultations to manufacturing and delivery, our team works to nurture our client relationships and industry partnerships to retain our status in the field.

We have a reputation as a go-to market provider that regularly surpasses our client expectations and needs, with the capacity to accommodate small scale projects up to large commercial needs. Dedicated to maintaining our position as one of Melbourne’s leading suppliers, our commitment to quality, customer service, and efficiency guides all of the work that we do.

Instead of outsourcing your manufacturing and cutting to overseas suppliers, speak with the KNS Metals team to see how you can streamline your production processes from an Australian provider who understands the local market.

If you’re interested in learning more about how we can provide you with excellent products and services, speak with one of our in-house experts today.

Capabilities:

- 250 ton bending force

- 4200mm bending length

- any parts, small or big, in mild steel, aluminium, galvanized and stainless steel.

- We can fold 0.5mm to 8mm material thickness and up to 4200mm in length.

- Services: 7 axis CNC (Y1, Y2, X, R, Z1, Z2 & Crowning)