Why Invest in Tube Laser Cutting for Your Project?

Time is money in any industry, and introducing innovative solutions like 3D laser cutting can offer a range of benefits that not only speeds up production times, but also ensure consistent, premium results.

A full list of the benefits found with tube laser cutting services includes:

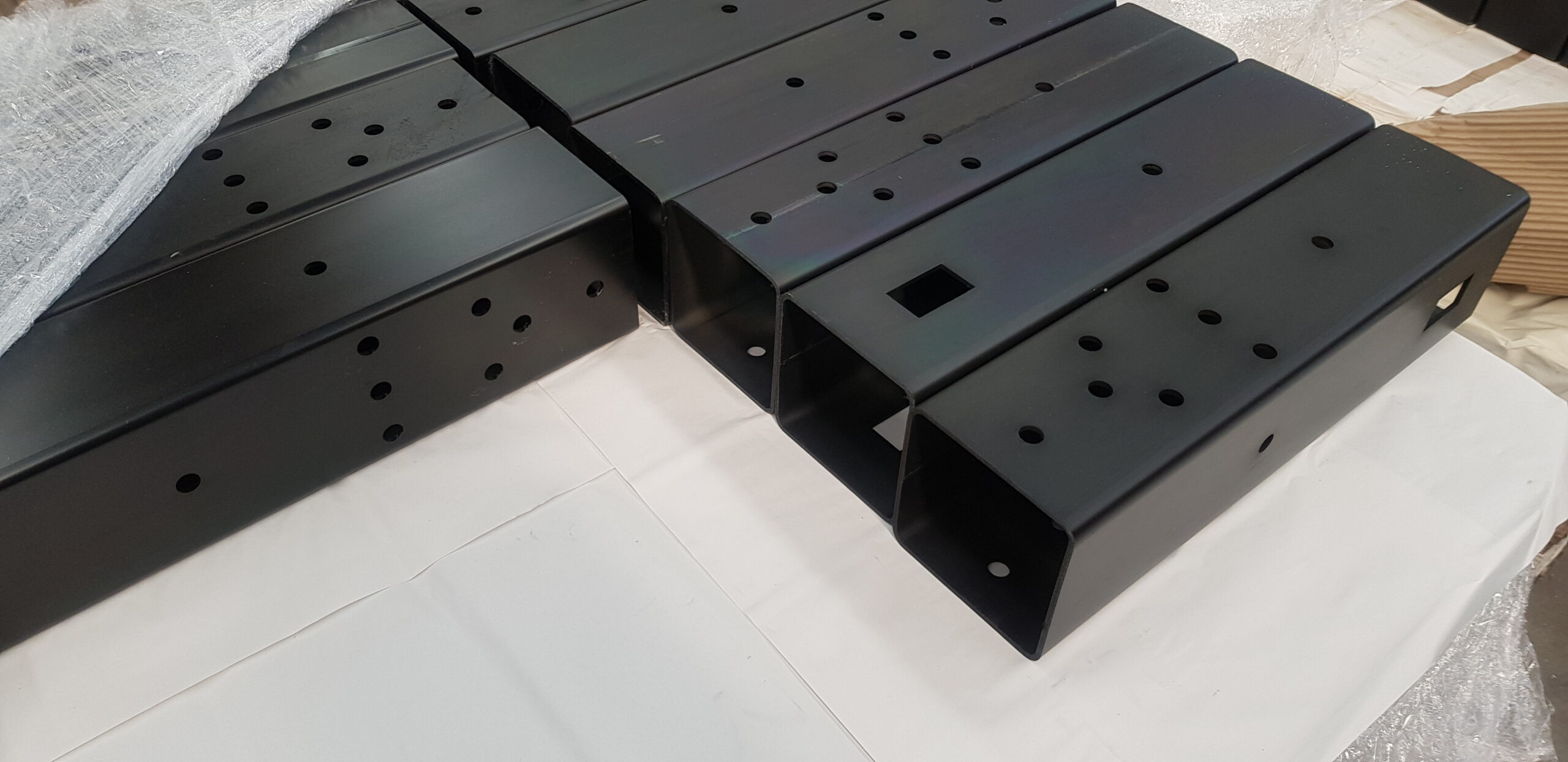

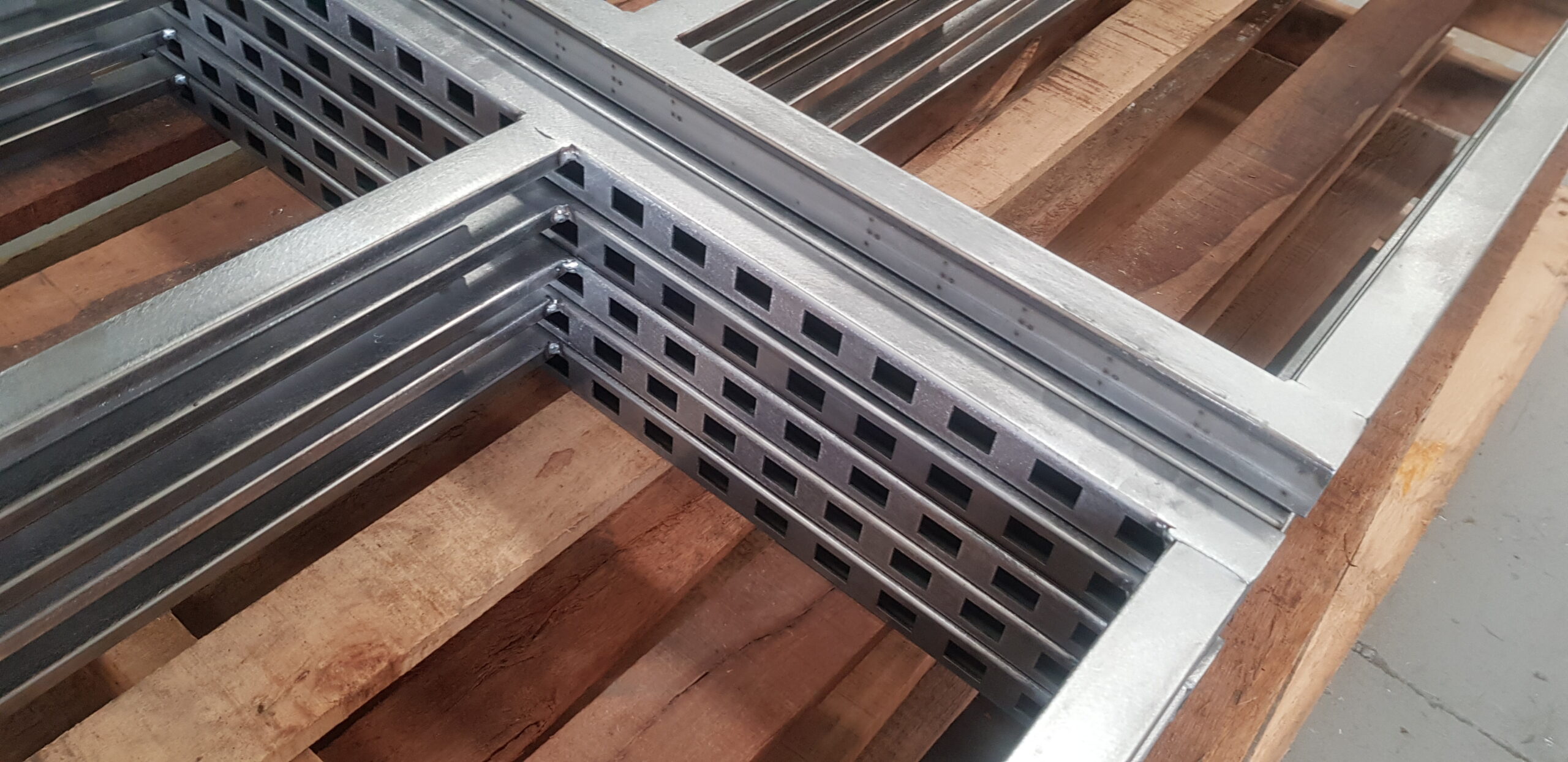

- High Precision: tube laser cutting offers exceptional accuracy, assured to within +/-0.1 mm, leaving it capable of creating intricate designs and patterns on steel beams, sheet metal, tubes and cylinders with high precision.

- Speed and Efficiency: Due to its automation and the fact that no other tools will need to be exchanged within the process, tube laser cutting can significantly increase production speed compared to traditional mechanical alternatives, making it an ideal solution for small and large-volume orders.

- Versatility: This technology can be used on a wide variety of materials, including metal, plastic, wood, glass, and more.

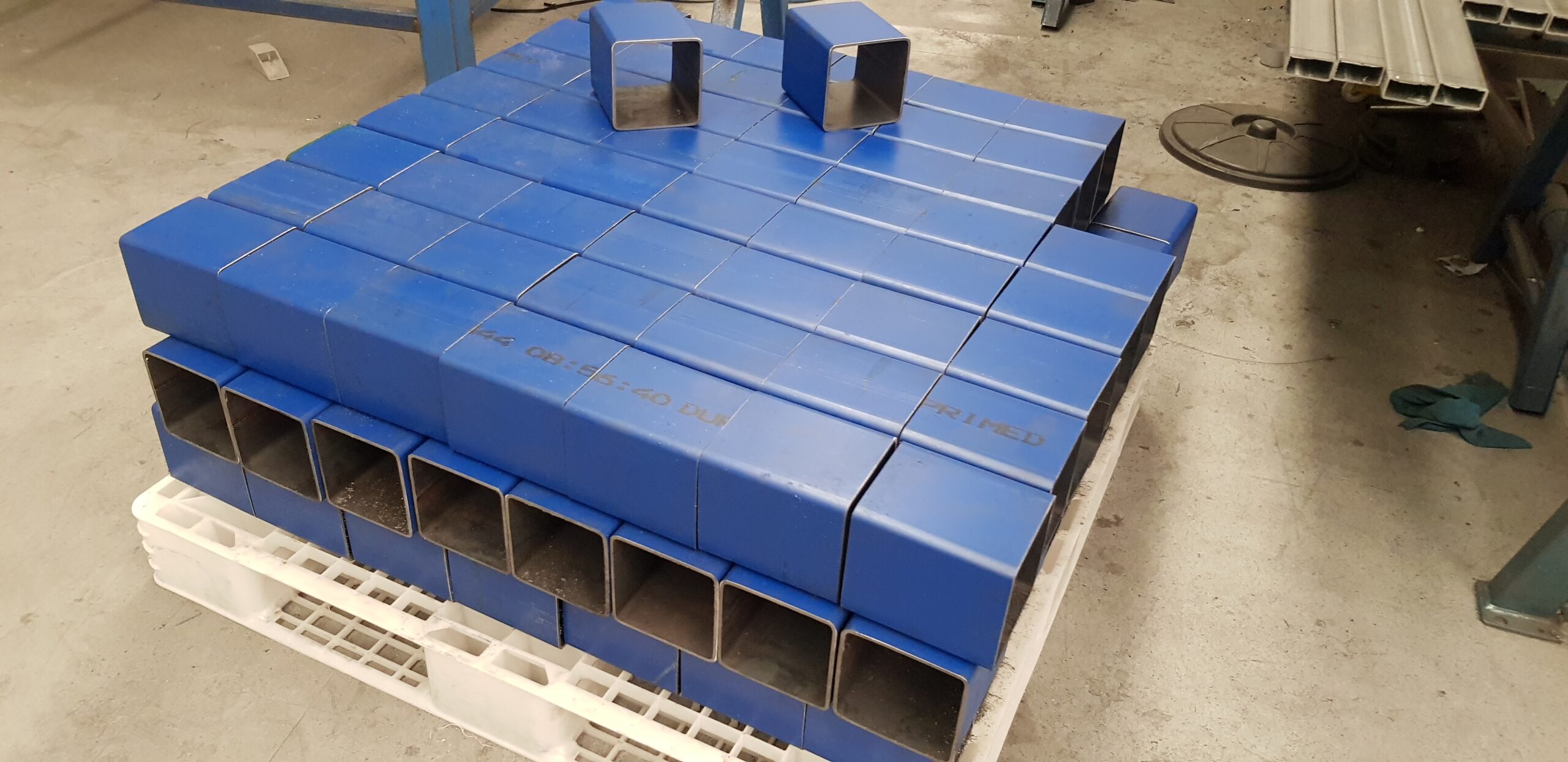

- Consistent Quality: A tube laser level provides excellent repeatability, ensuring each cut is consistent with the last, regardless of production volume. This investment guarantees quality with mass-produced items created in a short time.

- Minimised Material Waste: The precision of sheet & tube laser cutting results in minimal waste, making it a far more environmentally friendly and cost-effective option for engineers to adopt.

- No Contact Cutting: As a non-contact process, tube laser cutting eliminates tool wear and deformation associated with traditional mechanical cutting methods.

- Flexibility: Able to accommodate changes quickly, it is highly suitable for custom jobs and prototypes without the need for expensive tooling changes.

- Reduced Post-Processing: High-quality cuts often require little to no post-processing and after-treatment, saving both time and money in the overall production process.

Which Industries Can Benefit from Professional Laser Cut Components in Melbourne?

Tube laser cutting is an invaluable process for many industries, such as:

Construction

For constructions to meet specific regulations and standards, be durable and stand up to weather events, precision is essential. This technique is being incorporated into construction tasks more and more as it delivers that precision with unique and bespoke designs.

The sheer speed of this form of fabrication means you can improve your project lead times and increase your economy of scale by producing multiple components at once.

Mining

The requirements of mining operations are more diverse than almost any other industry, which is why the tube technique is the perfect solution. The automated process and no need to change tools mean a wide variety of products can be cut into shape in a very short period, making this process ideal for all mining operations. This extends to replacement parts for machinery.

Architectural and art

The beauty of this method is that the same accuracy that speeds up the process can also create intricate designs. It opens a new world for the design process of buildings and can also be used for modern, unique art installations.

Manufacturing and engineering

There is little room for error when it comes to mass production. The precision of this procedure makes it the preferred choice of engineers in all manufacturing operations.

Shop fitting and retail fit-outs

You don’t have to adopt a cookie-cutter approach and use off-the-shelf fit-out options for your brick-and-mortar outlet(s). Lasers allow you to have precise, bespoke fit-out solutions to tailor your shopfront to your requirements and make it attractive to customers.

Hobbyist requirements

Tube cutting isn’t just about the mass production of industrial products. Hobbyists are rapidly adopting it as the creative potential is enormous. 3D shapes can be cut into shapes as quickly and accurately as flat materials. There is also scope for engraving, carving, unique shapes, patterns and designs.

Speak with KNS Metals to Explore More with Our Tube Laser Cutter Services for Your Metal Sheets, Steel Beams & More

Ready to revolutionise your production process with high-precision tube laser cutting services? Look no further than KNS Metals.

Traditional flatbed laser cutting services are also available for all your precision metal needs. We have the latest technologies for the precise fabrication of all metals for the manufacturing industry and other requirements.

We are your premier metal fabricators in Melbourne. If you would like to learn more or get started with our services, please contact us at (03) 9706 4808 or email through your specifications to sales@knsmetals.com.au.