3D Laser Cutting Technology: 5 Things You Need to Know for Industry Success

As industries continue to evolve, 3D laser cutting technology has emerged as an essential tool for various applications. This innovative method has transformed how we process materials, from metals to ceramics, and enabled unprecedented precision and efficiency.

For businesses and professionals alike, staying informed about 3D laser cutting technology is crucial. Not only can it help you identify new opportunities and streamline processes, but it also plays a key role in maintaining a competitive edge in today’s fast-paced market.

In this article, the specialists at KNS Metals explore everything you need to know about 3D laser cutting for metal like steel and aluminium, as well as the common tools for industry applications.

Tracing the Origins of 3D Laser Cutting Technology

Early Laser Cutting Systems

Laser-cutting technology dates back to the 1960s when researchers first harnessed the power of lasers to cut materials. Initially, these systems were primarily used for industrial applications and focused on cutting flat surfaces.

The Evolution of 3D Laser Cutting

Over time, advances in laser technology and computer-aided design (CAD) software led to the development of 3D laser cutting systems. These machines introduced a new level of versatility, allowing for complex geometries and intricate designs.

Today’s State-of-the-Art 3D Laser Cutting Technology

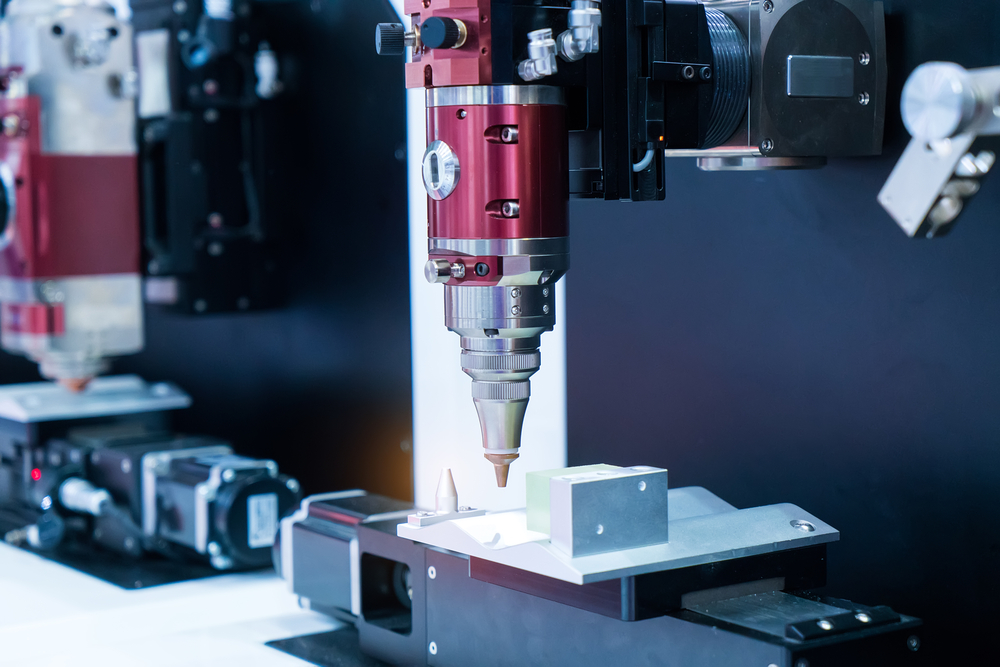

Modern 3D laser cutting machines have come a long way, integrating advanced features like fibre lasers and automated material handling systems. These improvements have significantly enhanced the capabilities of laser cutting for metal, tube cutting, and more.

Essential Components of 3D Laser Cutting Machines

Laser Source

The laser source generates the highly concentrated beam of light necessary for cutting. Common types include CO2, Nd:YAG, and fibre lasers, each offering unique benefits and drawbacks.

Optics and Beam Delivery System

This system directs and focuses the laser beam onto the workpiece. High-quality optics ensure minimal energy loss and optimal cutting performance.

Cutting Head and Nozzle

The cutting head, along with the nozzle, controls the position and angle of the laser beam to achieve precise cuts and minimise material waste.

CNC Control System

A computer numerical control (CNC) system translates CAD designs into machine-readable instructions, allowing for the automation of the cutting process.

Material Handling and Automation

Modern 3D laser cutting machines often include automated material handling systems, increasing efficiency and reducing the need for manual labour.

Materials and Applications of 3D Laser Cutting Technology

Compatible Materials

- Metals: Steel, aluminium, and other metals are commonly cut using 3D laser cutting technology.

- Plastics: From acrylic to polycarbonate, laser cutting is also suitable for various plastic materials.

- Ceramics: Advanced ceramics can be processed using laser cutting, enabling intricate shapes and designs.

- Composites: Composite materials like carbon fibre can also benefit from the precision of laser cutting.

Industries and Applications

- Automotive: 3D laser cutting is widely used in automotive manufacturing, from body panels to engine components.

- Aerospace: The aerospace industry relies on laser cutting for precise, lightweight components that cannot be controlled with the human touch.

- Medical: Laser-cutting technology is employed to create intricate medical devices and surgical tools at scale.

- Consumer Electronics: The manufacturing of smartphones, laptops, and other electronics often involves laser cutting processes to guarantee precision with high-production volume.

Advantages of 3D Laser Cutting Technology

Precision and Accuracy

One of the key benefits of laser cutting is its ability to achieve highly accurate and intricate cuts, making it ideal for complex designs and tight tolerances.

Speed and Efficiency

3D laser cutting technology offers rapid cutting speeds, allowing for shorter production times and improved productivity.

Flexibility in Design

With the ability to process a wide range of materials and shapes, laser cutting offers unmatched design flexibility.

Minimal Material Waste

Laser cutting’s precision reduces material waste, leading to cost savings and environmental benefits.

Reduced Need for Secondary Operations

The clean and precise cuts produced by laser cutting often eliminate the need for additional finishing processes, further streamlining production.

Improved Safety

Laser cutting is a non-contact process, reducing the risk of injury to operators and minimising wear on machinery.

Challenges and Limitations of 3D Laser Cutting Technology

Initial Costs and Investment

High-quality laser-cutting machines can be expensive, making the initial investment a potential barrier for some businesses. Engaging with professionals offering services related to rotary laser cutting can prove far more cost-effective and efficient.

Skilled Workforce Requirements

Operating and maintaining laser-cutting equipment requires specialised knowledge and training.

Limitations in Cutting Certain Materials

Some materials, such as highly reflective metals, can be difficult to cut using certain laser types.

Maintaining and Calibrating Equipment

Regular maintenance and calibration are necessary to ensure the longevity and performance of laser cutting machines, which can be time-consuming and require skilled technicians.

Environmental Concerns

Laser-cutting processes can generate fumes and waste materials, making proper ventilation and waste management essential for minimising environmental impact.

Learn More About Laser Cutting for Metal Applications with KNS Metals

As the technology continues to evolve, staying informed and engaged with new developments is key to maximising the benefits of 3D laser cutting for metal, tube cutting, steel laser cutter applications, and more.

For more information or to get started with our range of laser-cutting services in Melbourne, contact us at KNS Metals today.