Back to Basics: All About Galvanised Steel Metal Fabrication

For architects, engineers, steel fabricators, and many more, galvanised steel has become an incredibly popular resource for projects in an array of industries. In this comprehensive guide, our specialists at KNS Metals will explore what makes galvanised steel so popular and practical, detailing its manufacturing processes and uncovering its pivotal role in modern metalwork. Moreover, we’ll highlight the necessary tools in metalwork and numerous benefits of galvanised steel, showcasing why it’s a favoured choice in diverse applications, from sheet metal fabrication in Melbourne to robust steel structures across the globe.

What is Galvanised Steel?

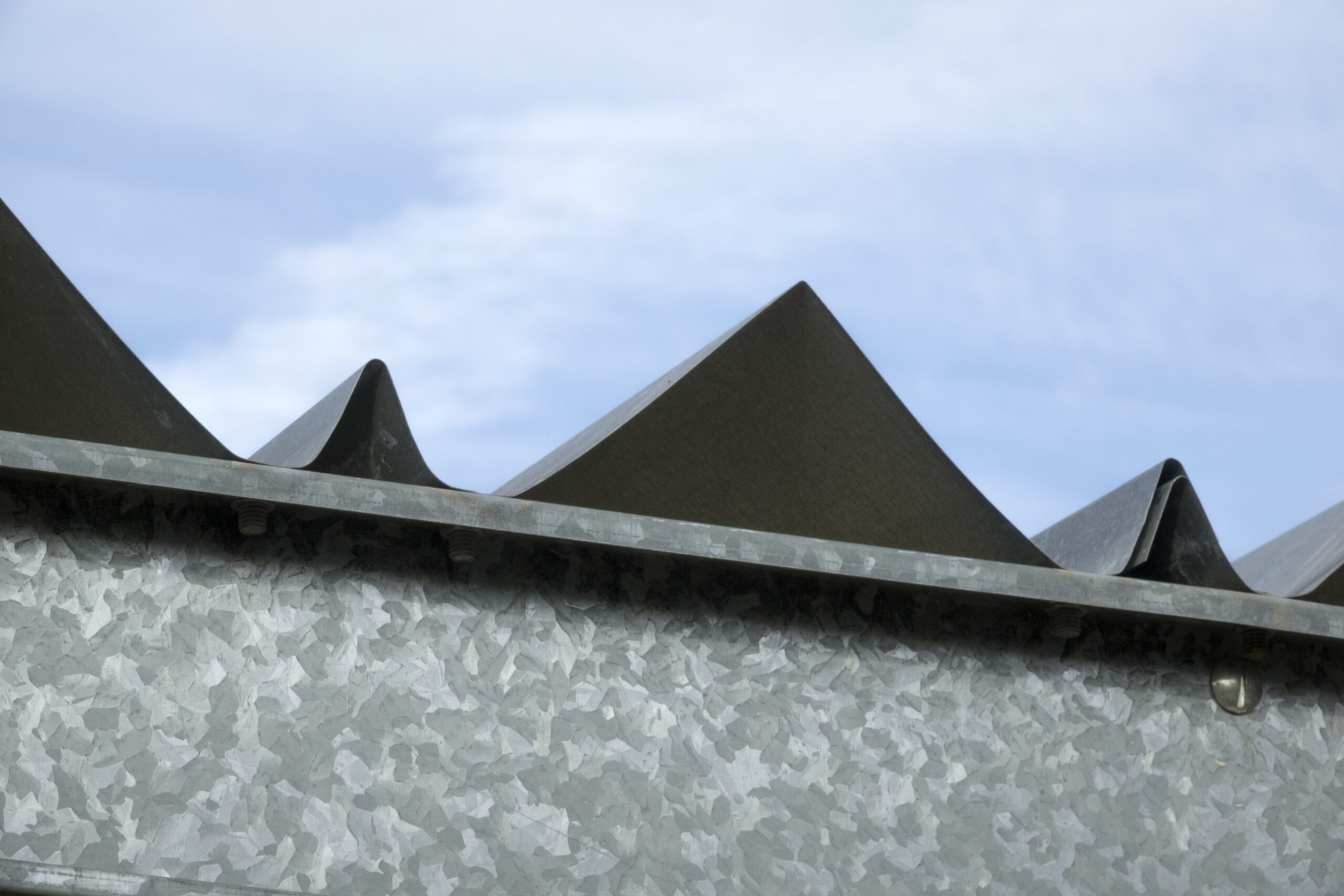

Galvanised steel stands out as a marvel of engineering. The material itself is not just ordinary steel, but a specialised steel that has been given a protective zinc coating through a process called galvanisation. The coating serves as a formidable shield, safeguarding the steel beneath from the ravages of corrosion and weathering, making it a cornerstone in the world of modern construction and manufacturing, Although not really a ‘new’ solution, galvanised steel remains the preferred synergy of strength and resilience, ensuring that the steel structures, whether they’re part of a towering skyscraper or a subtle piece of art, endure through time. Its versatility and durability make it an ideal choice for a myriad of applications, from steel fabricators in Dandenong to metal screens in Melbourne, not to mention mass production throughout the solar, automotive, construction and agricultural industries.

How Would a Steel Fabricator Create Galvanised Steel?

To create a product that has both the strength of a steel structure with the corrosion protection of zinc, a steel fabricator can rely on a host of options, including:

Hot-Dip Galvanising

Hot-dip galvanising is perhaps the most favoured method of steel fabricators for its efficiency and economic benefits. In this process, a fabricator will submerge steel into a molten zinc bath at approximately 460°C. The immersion forms a metallurgical bond between the zinc and the steel, where, upon extraction and exposure to the atmosphere, the zinc reacts with oxygen to form zinc oxide and subsequently with carbon dioxide to create a robust zinc carbonate layer. The layer is easily identifiable by its crystalline ‘spangle’ pattern. Suitable for both simple and complex shapes, hot-dip galvanised steel is versatile, capable of withstanding temperatures up to 392°F, beyond which the protective layer may deteriorate.

Galvannealing

Galvannealing is a technique requiring a bit more attention and sophisticated processes, merging the processes of annealing and hot-dip galvanising. The steel is initially hot-dipped and then immediately annealed, resulting in a unique matte grey finish. Doing so produces a zinc-iron alloy coating, which is excellent for welding and paint adhesion. The resulting product, ‘galvannealed steel’, is distinguished by its dull matte surface, offering enhanced protection while maintaining the steel’s fundamental properties.

Pre-Galvanising

Pre-galvanising is an innovative approach practised by steel fabricators, particularly in the early stages of production. It involves cleaning the steel sheet and passing it through a molten zinc bath, followed by immediate recoiling, to allow for rapid, large-scale galvanisation, producing steel sheets with a uniform coating. Pre-galvanising is particularly beneficial for creating a consistent protective layer across the steel, ensuring uniformity and durability in the finished product.

Electro-Galvanising

Electro-galvanising stands out as a unique method among galvanisation processes. Instead of dipping steel in molten zinc, this technique employs an electric current in an electrolyte solution, reducing zinc ions to metallic zinc that deposits on the steel. Typically implemented at the initial production stages, electro-galvanising ensures a precise, evenly distributed zinc coating, delivering a great degree of precision and uniformity, and making it a popular choice for steel fabricators aiming for high-quality, consistent finishes.

What Tools in Metal Work are Used to Create Galvanised Steel?

Creating galvanised steel requires a range of specialised tools and equipment depending on the process of choice, such as:

- Heavy-duty machinery for hot-dipping, like large galvanising kettles to hold molten zinc.

- Annealing furnaces for the combined heating process.

- Cleaning agents and rolling mills

- Electrolyte tanks and electrical current setups

Beyond these, common metalworking tools like shears, die-cutters, and welding equipment will help shape and assemble the final galvanised steel product, be it for steel structures in the Melbourne CBD or intricate metal screens on local Dandenong properties.

What are the Benefits of Galvanised Steel?

- Corrosion Resistance: The zinc coating provides a protective barrier, significantly increasing steel’s resistance to rust and corrosion.

- Longevity: Galvanised steel structures have a notably longer lifespan, especially in outdoor or harsh environments.

- Cost-Effective: Compared to other protective coatings, galvanising is cost-efficient, both in initial costs and long-term maintenance. Durability: The tough nature of the zinc coating makes galvanised steel more durable against physical damage.

- Sustainability: Galvanised steel is environmentally friendly; it’s 100% recyclable and reduces the need for frequent replacements.

- Low Maintenance: Requires minimal upkeep due to its robust nature, saving time and resources over the long term.

- Versatility: Ideal for a wide range of applications, from steel fabricators in Dandenong to sheet metal fabrication in Melbourne.

- Aesthetic Appeal: The spangle finish gives a unique aesthetic, adding value to the architectural and design aspects.

Explore How Galvanised Metal Can Improve Your Project with KNS Metals

KNS Metals are leading sheet metal fabrication specialists in Melbourne, Dandenong and surrounding areas, offering the latest solutions in galvanised steel. If you would like to learn more about how the services of our steel fabricators could assist with your project, please contact our friendly team today.