Flat-Bed vs. Rotary Laser Cutting – What’s the Difference?

Laser technology is used to meticulously slice through materials to certain specifications to achieve certain design outcomes.

From intricately cut wooden boxes to large scale complex glass designs, industrial laser cutting is now an integral technique used across a variety of industries – including aerospace, toolmaking, manufacturing and textiles. But did you know there are various techniques to achieve a range of outcomes?

Here we’ll explore two popular methods: Flat-Bed and Rotary. How do they work? Which method is better? Read on to discover the differences, similarities, types of projects supported by both approaches, and to decide which method is best for your next project.

What is Flat-Bed Cutting?

Flatbed (or flat sheet) cutting relies on a pre-programmed design, which has been pre-set through CAD software to guide a laser around the material.

Once set up, a high-powered carbon dioxide (CO2) laser beam is focused on the sheet through a range of both fixed and moving mirrors that allow intricate designs to be impressed as per the CAD specifications. During this process, a concentrated jet of air or nitrogen is released to support the containment of the debris from what’s being cut.

What Can You Cut Using a Flat-Bed?

A whole range of things can be cut using this method, including:

- Rubber

- Plastics

- Paper

- Leather

- Cardboard

- Wood

- Mica

- Carbon Fibre

- Some metals

- Nickel

- Titanium

- Brightform Electro Galvanised Steel

- Chrome

- Blackform Steel

- Brass

- Zirconium

Look around your house. Some items that may have been cut using this technique include cereal boxes, laundry bottles, gift bags, cosmetic box inserts, pet food packages, milk cartons and more.

Items that can’t be cut include:

- PCV pipes

- Standard glass

- Gold

- Porcelain

- Tiles

- Packing and insertable foam

- Silver

- Fabric

- Ceramic

What is Rotary Cutting?

Rotary cutting is a highly industrious manufacturing process that has successfully replaced traditional (and often more time-consuming) systems such as boring, sawing and pressing.

Using clamping technology, cylindrical items are loaded into the machine and rotated as lasers work to cut and engrave the material. The material is spun whilst the laser head moves along the rotary axis to the design specification.

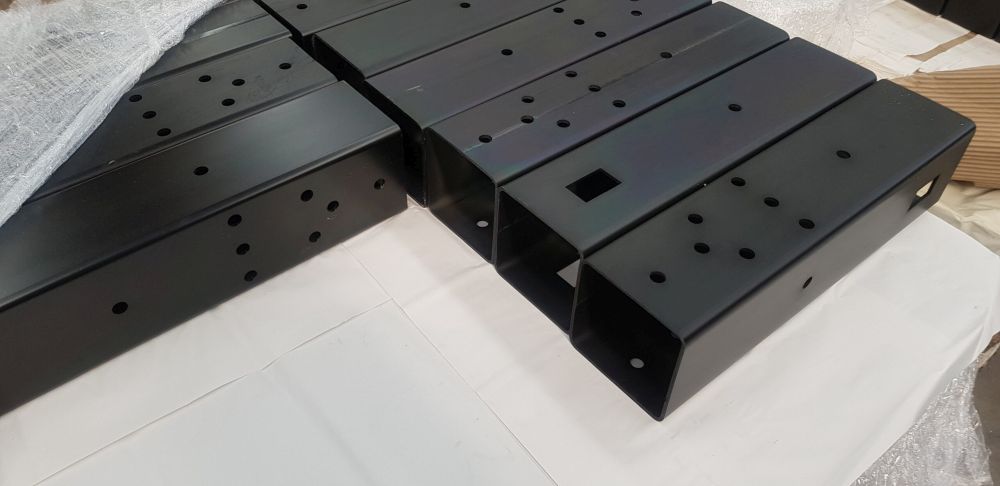

These machines are able to cut rectangular, rounded, squared and angled surfaces, making it extremely useful for complex projects in fabrication, metalwork and welding projects.

What Can You Cut Using a Rotary Cutter?

Stainless steel, mild steel and aluminium are three of the most common types of materials used for this.

Breaking it Down

Whilst both have their advantages and disadvantages, the flatbed method is great if you are working on large scale projects that require intricate cutting, whilst rotary is the go-to if you’re after 360° cut around a cylindrical material.

Still unsure on which style is right for you? Reach out to the KNS team today for advice and guidance on your next big project.