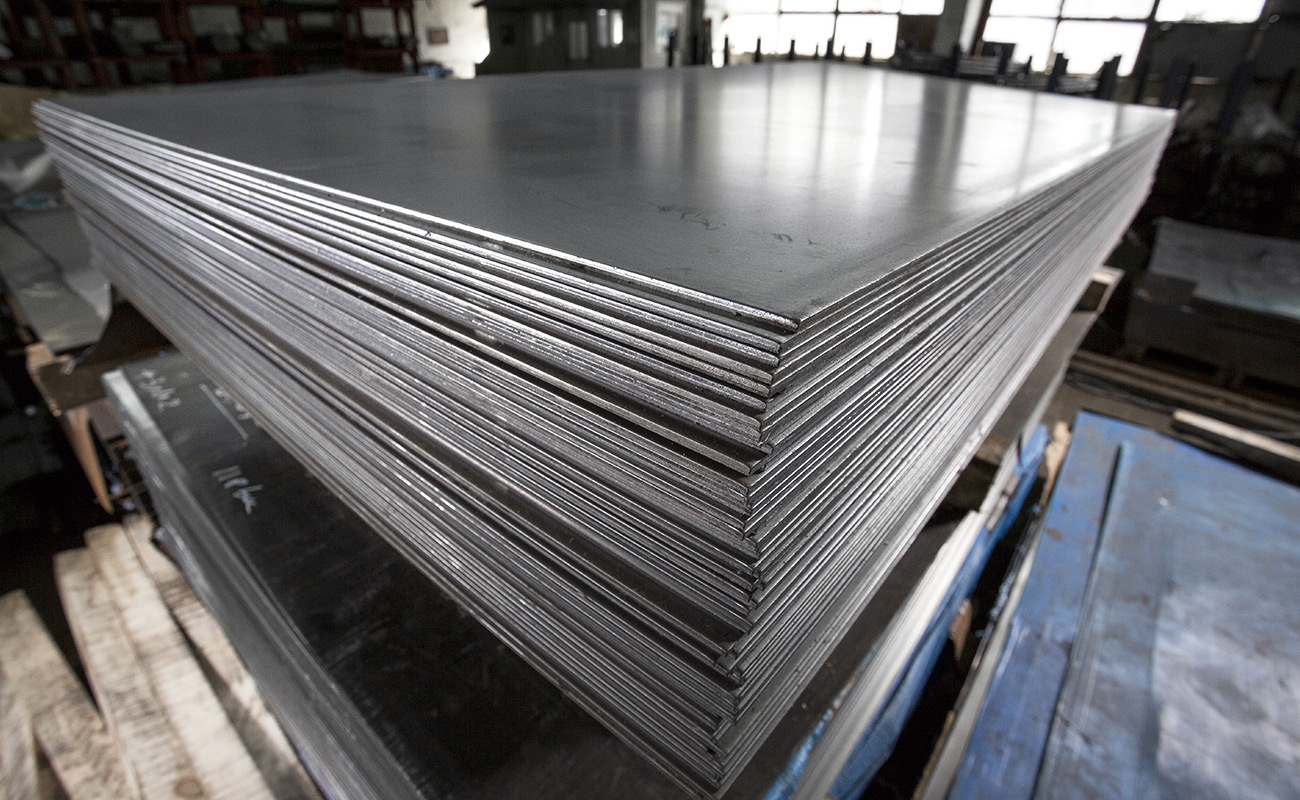

Stainless steel fabrication and how it works

Almost anything made of metal has been fabricated, making it an essential function for almost any business. Almost anything made of metal has been fabricated, making it an essential function for almost any business. Stainless steel is the perfect material for a wide range of applications because of its versatility. It is a strong material that is also malleable and can be bent, folded, welded and machined. It is also a perfect material for work-hardening, meaning the process fabrication will make the material stronger and more durable for use under heavy loads and in machinery that is required to work around the clock.

How does stainless steel fabrication work?

Steel fabrication is a dedicated skillset and you want to ensure you are dealing with experienced and talented workers when sourcing them for your fabrication needs.

They will employ a range of skills to transform raw stainless steel into the product you require, skills that include:

Friction sawing: This involves the use of a metal or circular blade just like regular sawing, but this is done at much higher speeds. The cut is achieved through the friction between the material and the teeth of the blade. The high speed causes frictional heat which allows for precision cutting.

Cold sawing: As the name suggests, this process keeps both the steel and the blade cool by transferring heat into the debris created by the blade. The means there are fewer sparks, less likelihood of discolouration and no metal dust.

Flame cutting: Sometimes the best fabrication method is to not use a blade at all. This process uses an Oxy-Acetylene torch to separate and shape components while it also generates enough heat to cut as well.

Laser cutting: This is a relatively new innovation that provides extreme precision. These industrial lasers require extreme skill and a steady hand to operate but are highly effective for the perfect, clean cuts.

The benefits

Using the right techniques for the appropriate job means that stainless steel can be moulded into almost any shape for industrial use.

But there is a range of other benefits achieved through this process as well, including:

Durability: Through the hardening process (and the steel is already extremely strong) you will end up with an extremely durable product that is also resistant to corrosion while remaining tensile.

Cost: This is an extremely cost-effective material and process making it popular across a wide range of applications.

Safety: Stainless steel is highly resistant to fire, water and acts of nature like storms and earthquakes.

Sustainability: Stainless steel is fully recyclable which is important in a world where reducing your carbon footprint is becoming an essential business function.

KNS Metals has over 30 years of experience in the fabrication industry and has developed products using industry-leading technologies and innovations over this time. Our advanced techniques and state-of-the-art technology mean you will get the highest standards of cutting and folding across all projects.