Equipment and Tools Used for Metalwork

Inside our Toolboxes: The Equipment and Tools Used for Metalwork

At KNS Metals we are often asked about the tools needed to complete certain jobs.

It is difficult to put together a comprehensive guide, as each metalworker has different methods, are looking to achieve different goals and will require their own set of tools to complete their tasks. But we can offer a basic guide to the best tools to pack into your kit and the entry-level requirements for all metalworkers at KNS Metals.

Traditional tools – including the trusty oxy-fuel torch

There are some metalwork tools that have stood the test of time and remain just as important today as they did many, many years ago.

Of course, there are the obvious essentials of the trade – like hand tools like files, saws, mallets, hammers and snips – that are always needed. But one of the biggest innovations in metalwork came all the way back in 1901 when Thomas Fletcher invented the flame cutting process. This is also called oxyfuel cutting or oxy-acetylene cutting and these torches are one of the primary tools in our toolbox.

By combining extreme heat with pure oxygen you can get precision cuts on all forms of metal without any damage, charring or imperfections that will ruin the final product. The other, more traditional tools that we recommend every metalwork carry include:

- An angle grinder: For cutting, polishing and grinding. Ensure you have a variety of discs for different tasks and you will want a durable option as this tool will be used regularly.

- A set of fasteners: To clip sheets of metal together before joining.

- Shears: Throatless options are preferred as they can achieve a range of different cuts including curves and irregular shapes.

- Wire cutters: For all of your loose ends.

- A soldering iron: Essential for sealing joints, plumbing and heavy wires.

- Panel hacksaw: A lightweight tool that is great for work on very thin sheets of metal.

- Angle finders: Like the old saying goes, measure twice, cut once.

- A strong backpack: What might surprise some people is that a lot of metalworkers don’t use a toolbox at all, rather storing their tools in a strong backpack for better portability around the workshop.

- Personal protective equipment: Proper, certified respirators, face masks, eye protection, welding masks and protective gloves are essential in any toolkit.

KNS Metals offers the latest innovations in metalwork

Everyone in our team is well equipped and trained to use the full raft of tools, including the latest innovations.

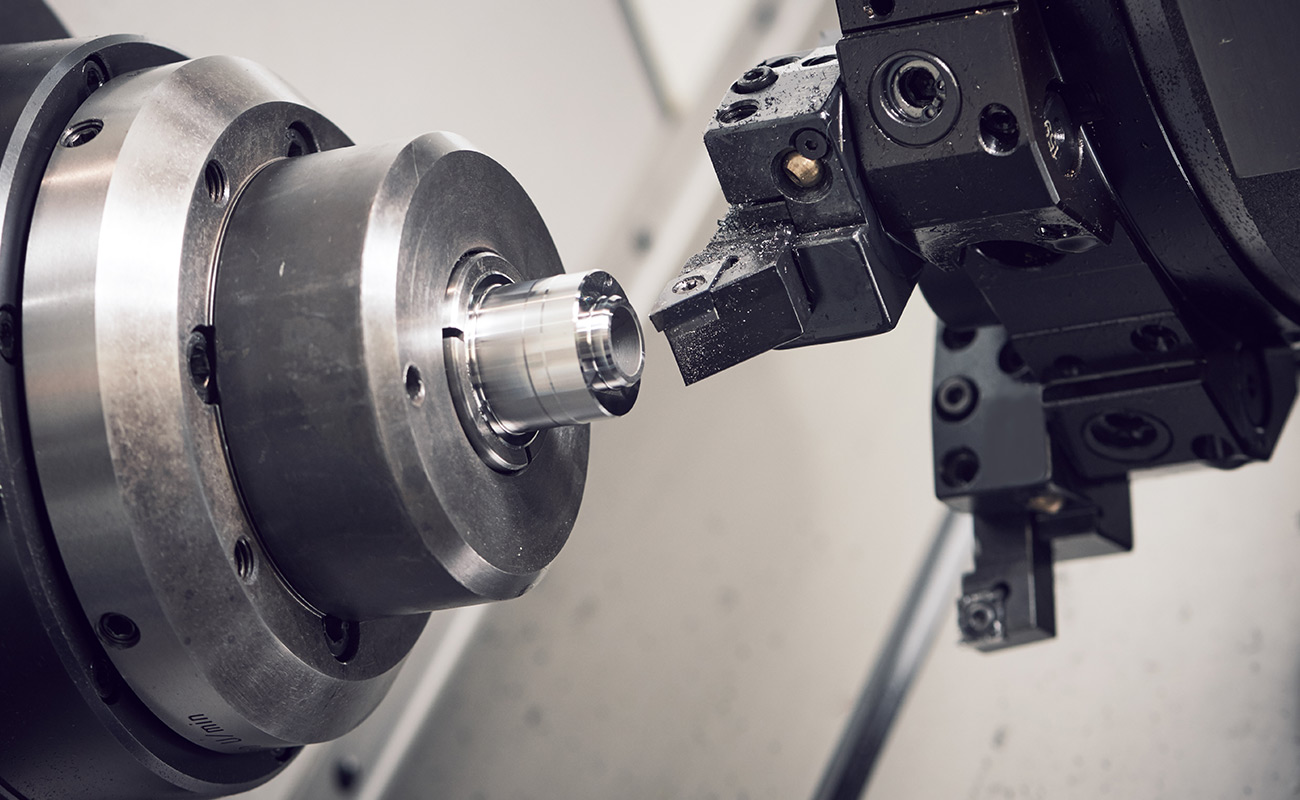

KNS Metals uses CNC (Computer Numerically Controlled) and CAD/CAM (Computer-Aided Design and Manufacturing) technologies to achieve perfection and precision on every project we take on.

This technology allows us to use modern, precision tools including laser cutting for decorative cuts and intricate projects and perforation for purposes like ventilation, heat management and noise dampening.

This CNC technology not only means greater accuracy, it means we can achieve results that cannot be achieved with traditional tools and all of this is delivered in a shorter time frame as well.