Industries That Benefit From Steel Laser Cutting

The need to cut and manipulate various forms of metal is widespread. So many industries and niches across the world depend on reliable methods for cutting that deliver precision and flexible design results within a safe and efficient practice. As such, the demand for metal and steel laser cutting in Melbourne and beyond has only grown in recent years, as it delivers all of these features and more.

In this article, the team at KNS Metals breaks down the advantages of steel laser cutting, as well as the various industries that can benefit from introducing a metal laser cutting machine or service into their operations.

What is Laser Cutting?

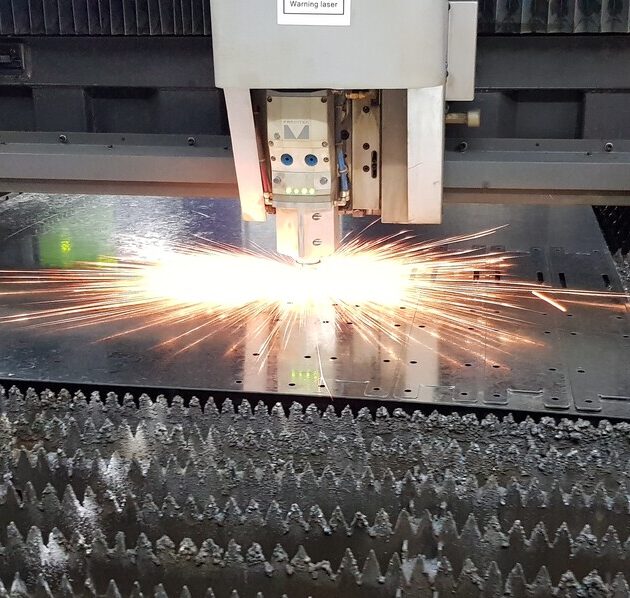

Laser cutting is a technology that uses a laser to cut materials, typically used for industrial manufacturing applications. Still, it is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser at the material to be cut. As a result, the remaining material will either melt, burn, vaporise, or blow away by a jet of gas, leaving a clean edge.

What are the Advantages of Steel Laser Cutting?

If you are looking for a way to improve your business and the products that you produce, you should consider making the switch to laser steel cutting as advantages include:

1. Increased Precision

Traditional methods can make it difficult to achieve clean, straight cuts on steel. However, with a laser cutter, you can easily perform precise cuts every single time. This means you can consistently produce higher-quality products and meet your customers’ expectations.

2. Faster Production Times

Again, traditional metal cutting methods can take a long time to cut through thick pieces of steel. With a laser cutter, the process is much quicker, allowing you to get your products out to your customers faster and improve your overall efficiency.

3. Reduced Waste

It can be difficult to achieve precise cuts without leaving behind metal scraps. When you use a laser cutter, the process is much cleaner and there is very little waste produced, saving you money on your overall production costs and improving your bottom line.

4. Improved Safety

Another significant benefit of steel laser cutting is that it can help to improve safety in your workplace. If you are using traditional methods, there is always the potential for accidents, given the variety of moving parts. Still, with a laser cutter, the process is much more simplified and refined, creating a safer working environment and reducing the risk of injuries.

5. Increased Flexibility

Traditional methods often limit users to cutting straight lines. However, a laser cutter can easily cut complex shapes and designs, allowing you to be more creative with your products and offer your customers more unique items.

Which Industries Can Benefit from Metal Laser Cutting & Design?

Using metal laser cutting and design can bring many benefits to many industries. This technology can help speed up production times, improve accuracy and precision, and create more intricate designs. If you work in any of the following industries, you may be able to benefit from using metal laser cutting and design technologies:

- Agricultural: Laser cutting can create highly precise parts for agricultural machinery, resulting in improved performance and longer life for each machine.

- Contract Manufacturing & Fabrication: Many contract manufacturers currently use a metal laser cutting machine to produce custom parts for their clients. This allows them to create complex shapes, designs and geometries that would otherwise be difficult or impossible to produce.

- Military: The military also uses metal laser cutting machines to produce a variety of parts and components, including armour plates and small arms parts. The process allows better maintenance of the highest standards of quality and performance.

- Construction: Many building organisations utilise laser steel cutting to create a variety of parts and equipment for construction projects, including everything from metal studs and beams to door and window frames.

- Automotive: The automotive industry has embraced laser cutting technology to produce various parts for cars and trucks, such as engine components and exterior trim pieces.

Contact Us at KNS Metals to Learn More About the Benefits of Steel Laser Cutting In Melbourne

KNS Metals offer high-quality and reliable metal laser cutting services for clients across Melbourne and the surrounding suburbs. If you would like more information, please contact us today by calling (03) 9706 4808.