Is laser cutting accurate?

Fine laser cutting is the perfect technology for specific requirements, usually in relation to manufacturing medical components and tools.it also allows designers to get a highly precise design in terms of pattern and shape, for specific devices in the pharmaceutical industry.

From surgical tools used for biopsies and cutting, to puzzle chain linkage for flexible endoscopes, distinct tips and side-wall openings – laser cutting provides higher quality, precision and speed, as opposed to traditional techniques.

As technology continues to advance, more and more innovation is becoming readily available to the sector. This includes a five-axis motion package that provides the freedom to cut more challenging geometries in one attempt.

Successful use of this kind of technology relies on adequately integrating the system’s components into a process that works well. The motion, tooling and software must all work simultaneously to get the necessary end product.

KNS, as an industry leader in state-of-the-art laser cutting technologies, is here to discuss the benefits of utilising this advanced technology in creating specific products for your needs.

KNS uses latest Fibre Optic Technology which is eco friendly and Energy efficient

Benefits of laser cutting

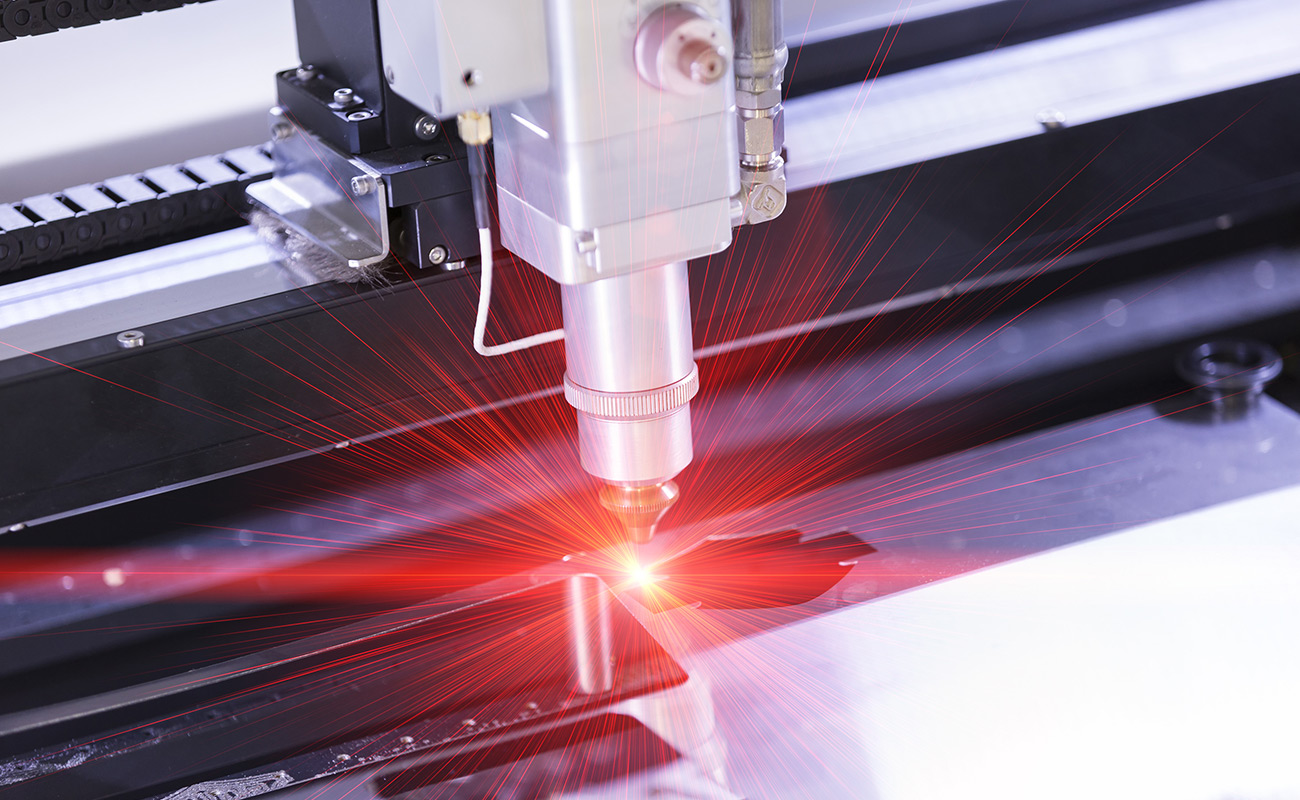

Laser cutting is ideal for several applications because the light does not have any physical presence and doesn’t come into contact with any material. It does not drag, impart force or push an area that might bend an aspect or cause flex that would have a negative impact on process control.

It also provides minimal thermal input, with particular control over work area temperature. This is vital as small parts heat quickly and might otherwise deform or overheat.

The process is also highly focusable to around 25 microns, which is about a quarter of the width of a single strand of human hair. This makes it possible to remove the minimum material amount needed to make the incision. This, in turn, results in extremely high accuracy and high precision.

Laser cutting technology has extremely precise control of power, pulse width and focuses spot size. As laser cutting technology does not require touching the component, it can be oriented to make any form or shape. It is not limited by physical cutting geometry and can be utilised to create unique patterns.

Contact KNS to find out more

KNS is Melbourne’s leading provider of solutions just like this. We provide state-of-the-art laser cutting technology for businesses across Australia and are always happy to provide our valued clientele with the highest standard of service and communication.If you have any enquiries regarding our products, then please feel free to get in contact with our friendly team of staff.Fill out an enquiry form on our contact page or call us on 03 9706 4808 and we will help you out with all your questions.